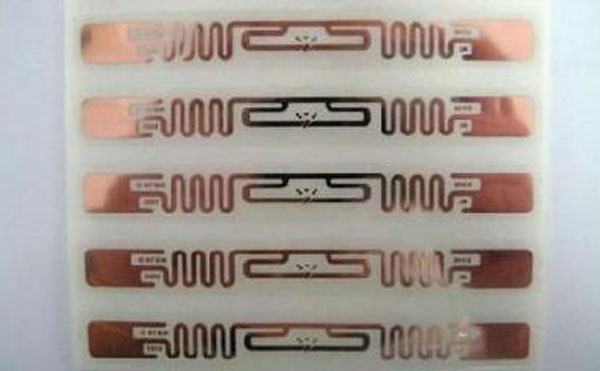

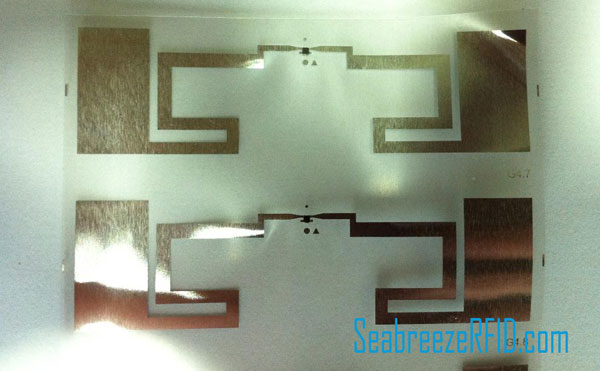

The antenna production process of the Fragile Label Etch Antenna is the same as that of an ordinary etched antenna. Their difference is mainly in different material structures. The fragile etched antenna adds a special material between the aluminum/copper thin layer and the PET substrate layer. The characteristic of the fragile antenna is to realize the uniqueness of the electronic label, ie, "the tear is destroyed immediately",  and when it is made into a label, it is attached to a flat and clean surface such as a seal, glass, plastic, and carton packaging. When the fragile tag is lifted, the tag or antenna cannot be completely lifted at this time and will be torn to achieve the effect of destroying the tag, so that the tag cannot be reused repeatedly.

and when it is made into a label, it is attached to a flat and clean surface such as a seal, glass, plastic, and carton packaging. When the fragile tag is lifted, the tag or antenna cannot be completely lifted at this time and will be torn to achieve the effect of destroying the tag, so that the tag cannot be reused repeatedly.

The Fragile Label Etch Antenna can use HF 13.56MHz or UHF 860MHz-960MHz. Antenna material (aluminum or copper) and size can be specified. You need to provide a DWG format CAD design file.

The Fragile Label Etch Antenna is used to produce tear is destroyed immediately RFID electronic tag.

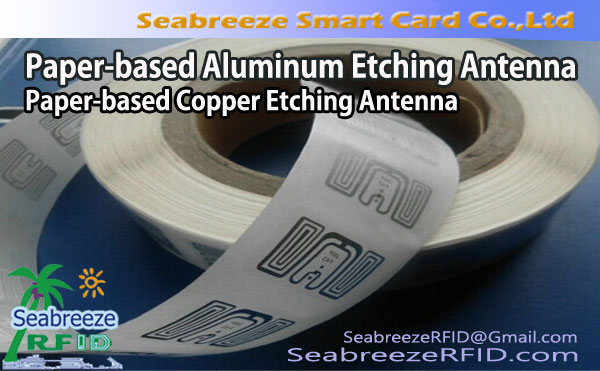

Custom RFID Etching Antenna

The customer provides the HF / UHF antenna design drawing, the file format AUTO CAD (.dwg), we quotes in 24 hours, the quoted expense includes the plate making expense and the product quotation, confirms the technical details, after signing the agreement, we will provide antenna layout within 24 hours – Customer Confirmation – Customer Confirm plate layout and pay plate fee – we arranges production plan – Plate making and sample production – Provide 20~400pcs free antenna samples to customer confirmation.

If the customer does not have an antenna design, then you need to provide antenna size specifications, bound chip models (for example: Ultralight, I CODE SLI-S, Alien H3, Impinj Monza 5), your binding machine model. We receive the above information within 24 hours to provide antenna design and pricing plate making fees and product pricing. Antenna Design Drawing Design Time: HF Antenna 7 Business Day, UHF Antenna 24 Business Day.