Miongozo ya Matumizi ya Printa ya Kadi

24/10/2025

Miongozo ya Matumizi ya Printa ya Kadi

Why do sample cards provided by our printing factory look stunning, bado kadi zilizoundwa kibinafsi wakati mwingine hupungukiwa? Here are some insights for reference.

1. Wakati wa kuunda kadi, hakikisha ubora wa picha sio chini ya 300DPI. Kwa picha, 300 DPI is sufficient.

2. Epuka kutumia kubwa, vitalu imara-rangi kwa asili. Hakikisha rangi zinakamilishana. Manufacturer sample cards undergo color separation processing, resulting in exquisite prints.

3. Beyond professional graphic artists adjusting image quality, you can also enhance card vibrancy by modifying printer parameters. (Walakini, we recommend only moderate adjustments to card printer settings.)

All card printers undergo factory color calibration. Each new printer includes a color test card demonstrating achievable results. With high-quality image design, you can reliably achieve expected outcomes.

Our technicians recommend optimizing printer parameters based on rigorous testing.

Using the Fargo 4250/C11/C15/C16 card printers as an example:

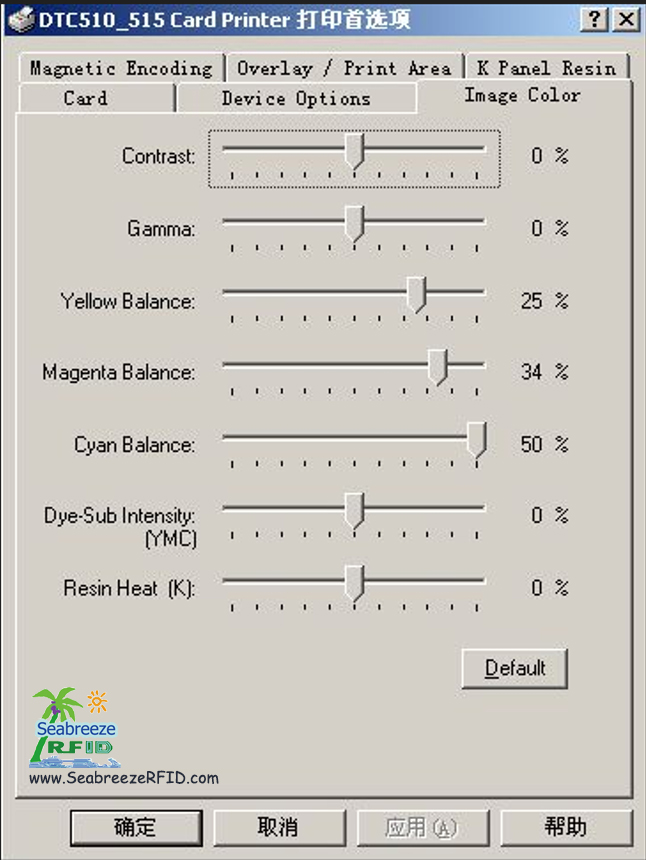

In the printer’s print preferences:

Contrast

Gamma

Yellow Balance

Magenta Balance

Cyan Balance

Dye-Sub Intensity (YMCB)

Resin Heat (K)

Adjust Contrast and Gamma as follows (Contrast: 15, Gamma: 5). All other settings may remain at default values.

If results remain unsatisfactory, slightly increase Dye-Sub Intensity (YMCB) kwa 10%.

For optimal printing of pure black text, set Resin Heat (K) between 25% na 30%.

(Chanzo: Shenzhen Seabreeze Smart Card Co, Ltd.)

Labda wewe kama pia

AIDC, E-tiketi, stika, RFID Label, NFC Mkanda wa mkononi, keychain, muda mahudhurio, Access Control

Nakili © 2013 | Shenzhen Seabreeze SmartCard Co.,Ltd. | Wa tovuti

Fung

Fung

Meneja wa mauzo

Meneja wa mauzo